Our PlanarPad™ CMP polishing pads are integrated with a specialized non-porous pad material technology, which has been practically applied across various CMP process domains. This technology demonstrates stable performance and reliability in diverse processing environments, offering our clients effective process solutions that enhance the stability and reliability of their processes.

The application of PlanarPad™ in the industry has showcased its practical capabilities in improving polishing uniformity, reducing surface irregularities, and prolonging the lifespan of the pad material. This technology not only meets the fundamental needs of our customers but also offers innovative and customized options, aiding them in addressing market competition.

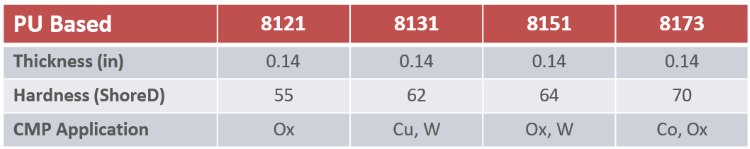

PlanarX Pad Products and Applications

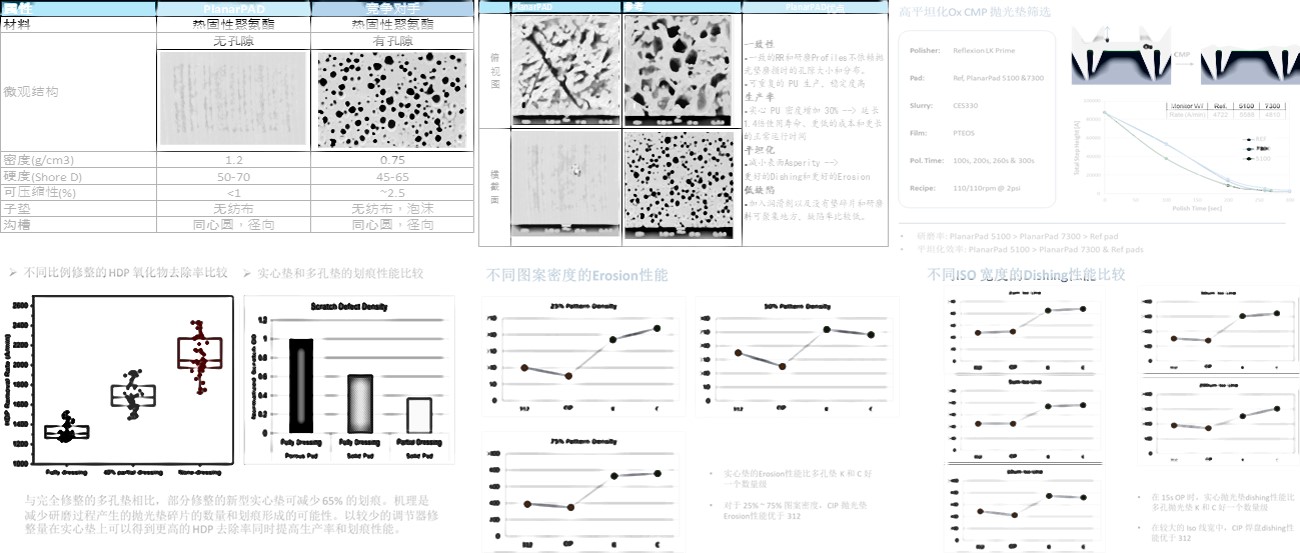

▍PlanarPAD™ Pad Technology Advantages

Our PlanarPAD™ polishing pad product has broken through industry technical bottlenecks, achieving a significant increase in remove rate, reduction in defect rate, and outstanding planarization capabilities.

▍Case study - Product Advantages

In our client-side testing, we conducted a comparative study covering planariztion, scratch defects, polishing rate, as well as dishing and erosion performance. The data clearly demonstrates that, compared to competitors'porous polishing pads, our PlanarPad™ new non-porous polishing pad has significant advantages in all these performance aspects.